Member Sign In Create Account

Login with email and password

No account yet? Register Now

THE FALLACY OF INSTANT BOURBON PART II - Science

In the last post, I talked about what quick aging whiskey producers claim, and why those claims are misleading. For Part II, I will attempt to address the shortcomings of each quick aging process compared to traditional 53 gallon barrel maturation. The main claims I will be challenging are the “replicating” and “accelerating” of barrel maturation, and the ages they claim to have replicated with a 6 month old whiskey. From there, you can decide for yourself if their claims are valid or misleading, or even relevant at all.

All of my sources are at the bottom. I know this post is long, but there is a lot these guys don’t do, so blame them.

Cleveland Whiskey places very young (6 months or less), sourced barrels of whiskey in a temperature controlled, pressurized steel tank that is full of chunks of treated barrel staves. By adjusting the temperatures and the pressure in the tank, they manually force the whiskey in to and out of the oak numerous times every hour. Cleveland says one cycle, just one shake, of their proprietary washing machine/paint-shaker-thingy technology is equivalent to a full 24 hour day in traditional barrel maturation. This means if he can run 100 cycles per hour, he can age his whiskey a full year in just over 3.5 hours, or 4 years in 14 hours (thanks r/bourbon). His process takes about a week per batch and there is an unspecified “resting period” after the process.

Much like small barrel maturation, Cleveland’s process should extract a much greater amount of oak compounds than traditional maturation. This is where they get their color, and if you have tasted Cleveland, this is also where they get a very large majority of their flavor beyond new-make. Wood.

Terressentia’s patent-pending TerrePURE technology is actually pretty interesting. It takes six month old barrels of whiskey, puts them in plastic tanks, and exposes the liquid to ultrasonic waves and a steady stream of oxygen. The website says this process, “reduces several known congeners (such as methanol, isobutanol, amyl alcohols, propanol, methyl alcohol, and free radicals) to a greater degree than any other industry method” and also, “induces a conversion of certain harsh-tasting acids to smooth-tasting esters”. Terressentia says that just 8 hours of their TerrePURE process creates a whiskey equivalent to, or better than a whiskey traditionally aged for 4 to 6 years.

The reactions mentioned are reactions that take place in the barrel. Esterification is one of the most important reactions in terms of developing aroma and making a profile sturdy to oxidation after bottling, and chemical degradation of low boiling distillation compounds like methanol, and high boiling distillation compounds like propanol, isobutanol and amyl alcohols is definitely another important aspect of maturation. Saying that all acids are harsh or hinting that acids in general are unwanted is wrong (3), but esterification is a goal, so all together, their aim is fairly true.

But if you are familiar with Aristotle, you know that the whole can be greater than the sum of its parts. Meaning just because these processes includes the same components of traditional barrel maturation (i.e. the barrel, grain distillate, oxygen, interaction, etc.) doesn’t mean the outcome is going be the same after they rearrange their relationships.

The fatal flaw of both processes is that the barrel’s form is less fashion and far more function than they would have you believe. What the barrel does by placing a barrier of toasted and charred oak between a pool of high ABV grain distillate and a room full of partly humid, oxygen rich air is not something that can be replicated by putting that barrel inside of the whiskey (as Cleveland does) or by simply oxygenating previously aged distillate (as Terressentia does).

To start, the barrel is an amazing filter. The nasty sulphur rich compounds like dimethyl sulphide which make unaged distillate smell rancid and taste harsh are neutralized while in the char layer, as it comes in contact with oxygen passing through the barrel. In fact, in a four year old barrel of whiskey, the same age that both Cleveland and TerrePURE claim to obtain, more than half of the total amount of dimethyl sulphide is oxidized out in the char layer (1)(2). So if you don’t have whiskey absorbed into a stave with oxygen passing through, your whiskey will seriously struggle to neutralize those unwanted compounds.

Because Cleveland submerges their barrel chunks inside a tanked pool of whiskey, no substantive amount of oxygen interacts with these unwanted compounds while they are absorbed into the wood, therefore prohibiting that massive filtration process that takes place in a traditional barrel. Simple chemical degradation can get rid of some these compounds, which I believe is what is taking place in TerrePURE, but they provide no evidence that these specific compounds are being degraded, and no one that I talked to would know how that would even happen with what is being done. They also provide no rate of their reactions to insinuate that 8 hours of TerrePURE would replicate the rate of filtration in a full size barrel over 4 years.

Further, because both Cleveland and Terressentia’s whiskey only spends months in a barrel, and is then placed in non-permeable containers, evaporation is extremely limited. This may be good for the bottom line, as you get to keep and sell most of your volume, but simple evaporation also gets rid of many unwanted compounds like remaining dimethyl sulphide, acetaldehyde, ethyl hexonate, and of course, that pesky dihydro-2-methyl-3(2H)-thiopene (1). Without a route for evaporation, those compounds are stuck in the whiskey and dramatically stifle any true “maturation,” as most rational people would define the word (3).

Fun Fact: 25-30% of an American whiskey’s color is obtained in the first six months (7)

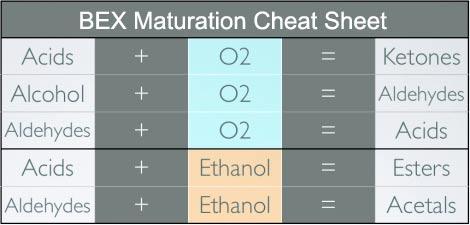

The decomposition of oak is another aspect of maturation that is missing from these processes. Through oxygenation and hydrolysis paired with the presence of alcohols, the barrel’s lignin and hemicellulose breaks down which allows for a constantly evolving source of maturation compounds to be extracted into the whiskey (1)(3). Those compounds then interact with a catalyst, like ethanol or oxygen, and they become new acids, aldehydes, esters, acetals, or ketones which were not originally available in the oak earlier during maturation (3). Those products reenter the barrel, create new reactions, and get extracted back into the whiskey to start the cycle all over. By removing the barrel from the process like TerrePURE, or by submerging the barrel in a oxygen poor liquid like Cleveland, you are disallowing the development of many of these diverse maturation compounds.

Terressentia points to “independent research” that validates the removal of certain high alcohols and unwanted congeners, but they only show two charts “proving” their process and they are both useless for our purposes because they show untreated vodka compared to treated vodka. To support the claims about TerrePURE replicating 4 to 6 years of barrel maturation, you would need gas chromatography-mass spectrometry data comparing the original untreated bourbon to the treated bourbon, as well as compared to a 4 year old, traditionally matured bourbon. Making vodka taste even less like anything is far from proving you can make 6 month old bourbon taste like 4 year old bourbon. In fact, it kind of proves the opposite.

So if these instant bourbon producers aren’t making their whiskey less young, how are they making them more “old”?

In Scotland, these processes are referred to as “masking” and can be done many different ways. Cask finishing is one way that is popular masking techniques across the globe for a myriad of reasons, as well as adding flavoring (like many of the “award winning” Terressentia products), but a process called “agitation” is popular here in the US.

Cleveland focuses solely on extraction through agitation to mask their young whiskey. They force whiskey into and out of the wood to load the liquid with lignin degradation products, or LDPs*. In traditional maturation, some LDPs reach their “sensory thresholds” quickly (the concentration that the compound becomes noticeable), around 6 months to 2 years in a full size barrel, so it is likely that both Terressentia and Cleveland’s sourced barrels of whiskey already have some compounds at high levels, and that Cleveland can obtain even more during their process. This sounds like maturation sped up, but extracting compounds from the oak is merely step one.

*LDPs: Gallic acid, vanillic acid, syringic acid, vanillin, syringealdehyde, coniferaldehyde, ellagic acid and scopoletin, as well as furfural (found in Scotch malt spirit) and 5-hydroxymethyl furfural (which is mainly associated with spirit caramel)¹

For example, while the abundant vanillin aldehyde reaches its threshold quickly (6 to 9 months), a truly mature vanilla profile of a well aged bourbon comes after each compound of vanillin’s ester chain (and acetal chains for some compounds) are also amassed to their sensory thresholds (1)(4). Vanillin (aldehyde), vanillic acid (acid) and ethyl vanillate (ester) are all contributors to that vanilla aroma and taste, but without hitting the threshold of each compound, or with only a large amount of one compound, the vanilla profile is fairly basic (4). The same concept applies to various aldehydes and acids that are found in the barrel which create fruit profiles, like apple, pear, and cherry, spices like cinnamon, nutmeg and clove, floral notes, and specific well developed earthy wood aromas like pine, tobacco and cedar.

Fig 1: Details from http://www.tuthilltown.com/wp-content/uploads/Long-Term-Changes-In-Whiskey-Maturation-Presentation1.pdf

Even if TerrePURE can convert the LDPs the whiskey obtained during the 6 months in the barrel to esters as they claim, they still only have 6 months worth of maturation compounds no matter how you shake it. Once they shift the LDPs to esters or acetals, they permanently deplete their supply of acids and aldehydes and have nowhere to get more. When a traditional barrel converts an acid to an ester, more acids can be pulled from the barrel or aldehydes can be turned into acids, which keeps a steady supply of each compound in the whiskey. TerrePURE can’t do this, and they only get 6 months worth of lactones and polyphenolics as well, which all severely limits the profile potential for TerrePURE whiskies, which brings us back to oak decomposition.

Because the barrels have so little time to decompose, the oak never gets to break down. This not only creates diverse congeners as mentioned earlier, but also allows for the whiskey to penetrate deeper into the barrel to get those congeners. Different LDPs are created at different depths, some as deep as 6mm into the stave (2)(6), and it is highly improbably that TerrePURE’s whiskey was able to get that deep after just 6 months. This means that the small amount of LDPs the TerrePURE whiskey has obtained in the 6 month barrel phase will only represent a small fraction of the variety of LDPs a traditional barrel will have obtained at the same 4 or 6 year mark Cleveland and Terressentia claim to have replicated.

Cleveland can extract a large amount of LDPs from the oak chunks in their tanks (as well as lactones), but their lack of oxygen prohibits the development of these LDPs. If the aldehydes are stuck as aldehydes, once they hit their sensory ceiling, they will offer nothing to the profile unless they can be converted to acids or acetals. There is plenty of ethanol inside the distillate to turn acids into esters or aldehydes into acetals, but with no more than a week to interact, there is very little time for these reactions to take place organically and their process does not “speed up” chemical reactions, just extraction. And since the polarity of water and ethanol molecules forces ethanol to cluster in the presence of water (5), and since Cleveland does not allow for evaporation of water, a large amount of ethanol will stay aggregated together during Cleveland’s “maturation” treatments and therefore largely unavailable for those desirable maturation reactions.

So Cleveland can extract oak products but hasn’t proven that they can convert them the same way a barrel can, and they can’t remove a majority of the unwanted compounds from distillation, all of which takes place at much higher levels over the course of 4 years in a 53 gallon barrel. They get lots of basic wood but very little evolution of the sweet, spicy and fruity ester and acetal chains.

Terressentia says they can manually shift maturation congeners and some alcohols to a more desirable state, but has no way to obtain a full spectrum of LDPs, lactones and polyphenolics once they remove the barrel. They also struggles to filter a number of unwanted products that don’t neutralize through simply oxidation, or at least haven’t proven that they can, and the vodka charts don’t cut it.

In other words, the barrel wins and it’s not even close.

If these techniques were to precede barreling, or be done subsequent to a longer maturation period (like say, 4 years), it could result in something very interesting. I have no problem with using science to bring better tasting products to the market, or if they were to simply say they made 6 month old bourbon taste “better” instead of equal to a certain age, but these claims of “accelerating” maturation to “replicate” 4 to 6 years of barrel maturation are way premature. Hopefully this long ass post proves that.

If you bothered to read this entire thing, I applaud you. If I see one, “but if the whiskey is good, who cares?” comment, I quit.

Per a comment below by Randall S., it would be very interesting to see what would happen if Cleveland Whiskey underwent the TerrePURE process. It seems like a very logical fit.

Sources

1. Whisky: Technology, Production and Marketing. Inge Russell. Print.

2. Aging of Whiskey Spirits in Barrels of Non-Traditional Volume. John D. E. Jeffery

3. Chemical Composition of Alcoholic Beverages, Additives and Contaminants

4. Characterization of the Most Odor-Active Compounds in an American Bourbon Whisky by Application of the Aroma Extract Dilution Analysis. Luigi Poisson, Peter Schieberle.

5. Long Term Changes in Whiskey Maturation. Tuthilltown.

6. Textbook of Wood Technology: Structure, Identification, Properties, and uses of the Commercial Woods of the United Staves and Canada. A.J. Panshin and Carl de Zeeuw. Print.

7. Production of American Whiskies: Bourbon, Corn, Rye, and Tennessee. R. Ralph.

Login with a social network